HYBRID & ELECTRIC DRIVES

A REFERENCE POINT

FOR SUSTAINABLE MOBILITY

Conscious of the role played by electrification, OMSI has created a clean energy division.

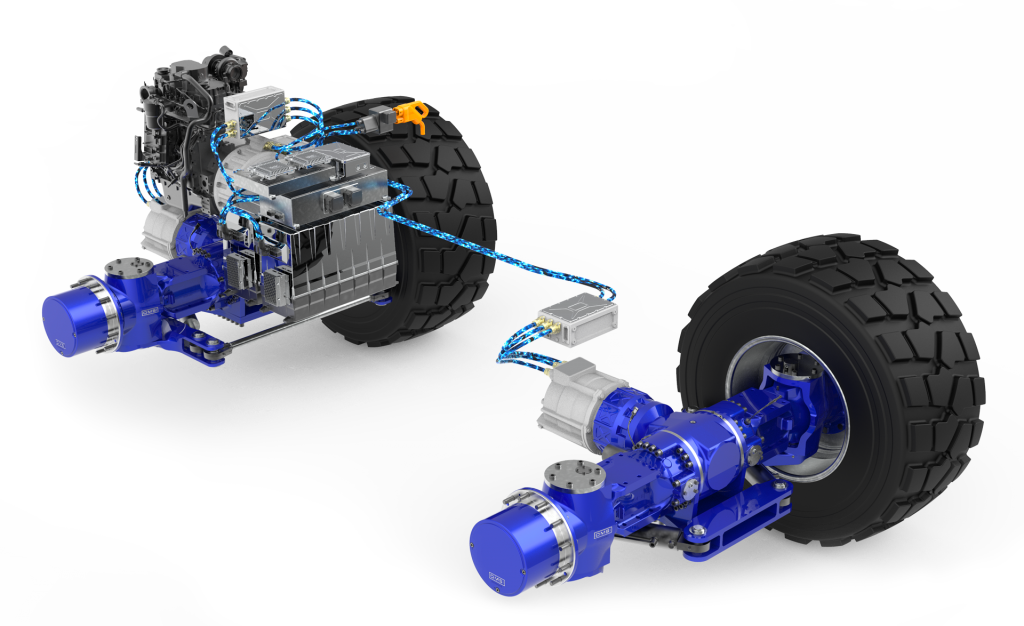

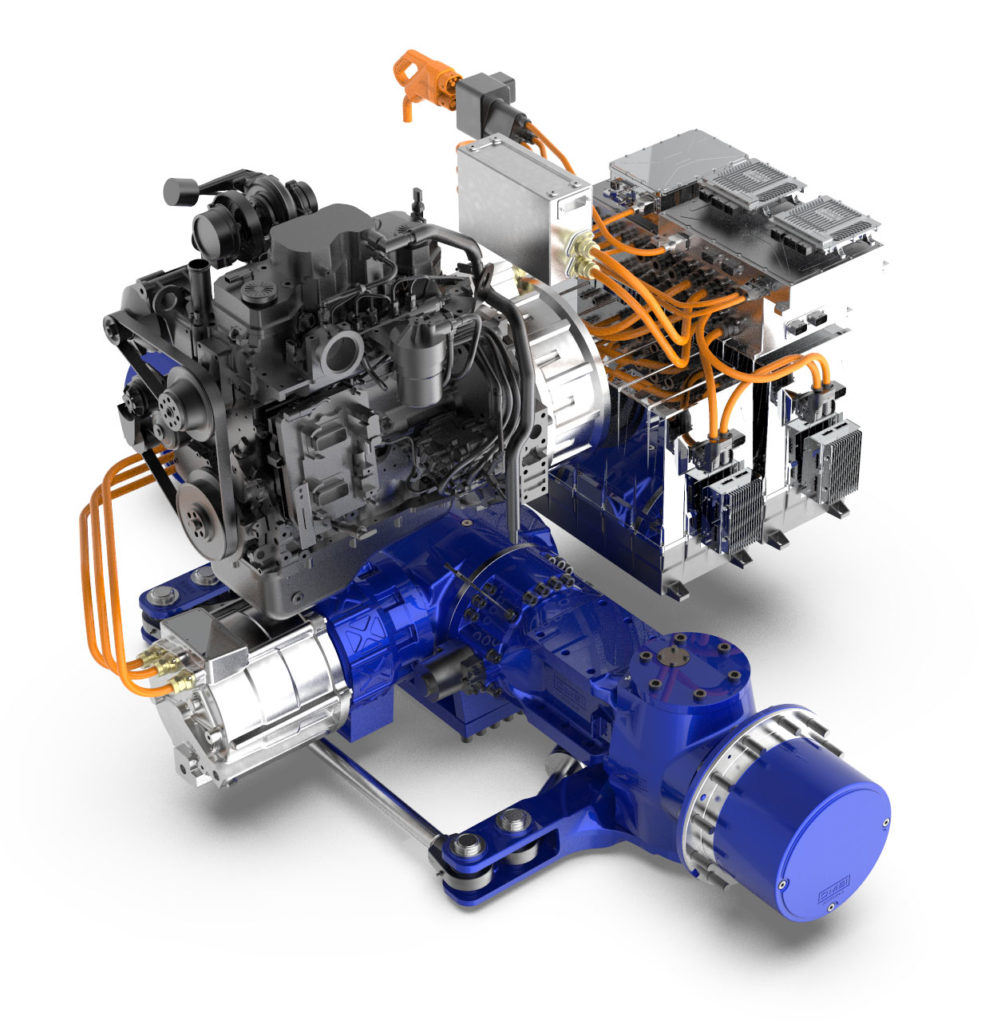

The new world of green mobility involves energy savings, reduced emissions and noise pollution, and meeting legislative requirements. OMSI can meet your needs by providing a variety of comprehensive solutions, such as complete drive lines including electric motors/generators, power electronics, storage devices, gearboxes and auxiliary systems for all-electric (EV), hybrid (HEV) or plug-in hybrid (PHEV) vehicles.

Integration with its standard product range has resulted in new dedicated drive units such as e-axles, e-hubs, and 2-speed Powershift e-gearboxes to meet ever growing requirements.

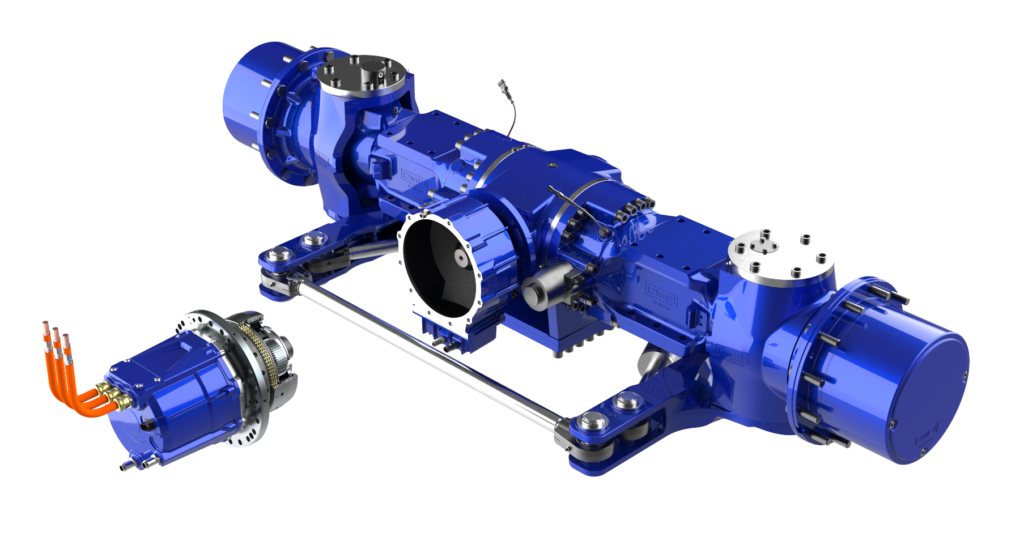

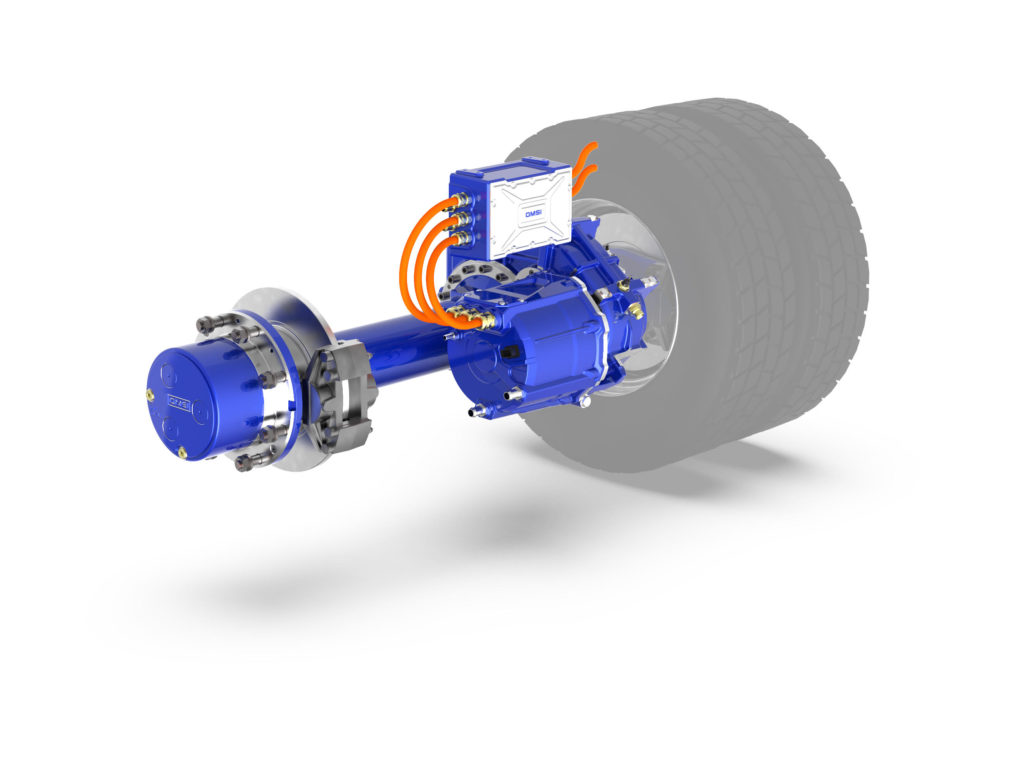

PARALLEL SHAFT E-AXLE

OMSI has developed specific axles for e-machines with parallel gears and lockable differentials, conceived to work with high power density E-motors, with imput speeds up to 13.000 rpm.

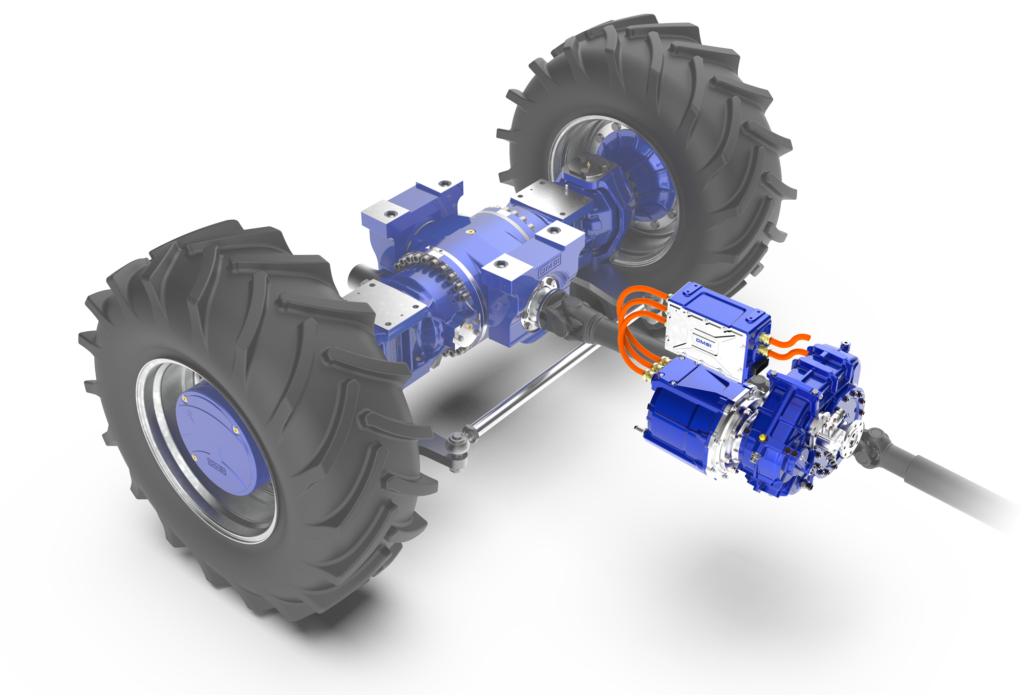

DROPBOX FOR E-MOTORS

High input speed dropbox for high power density electric motors with one or two outputs (2WD – 4WD machines) and integrated differential.

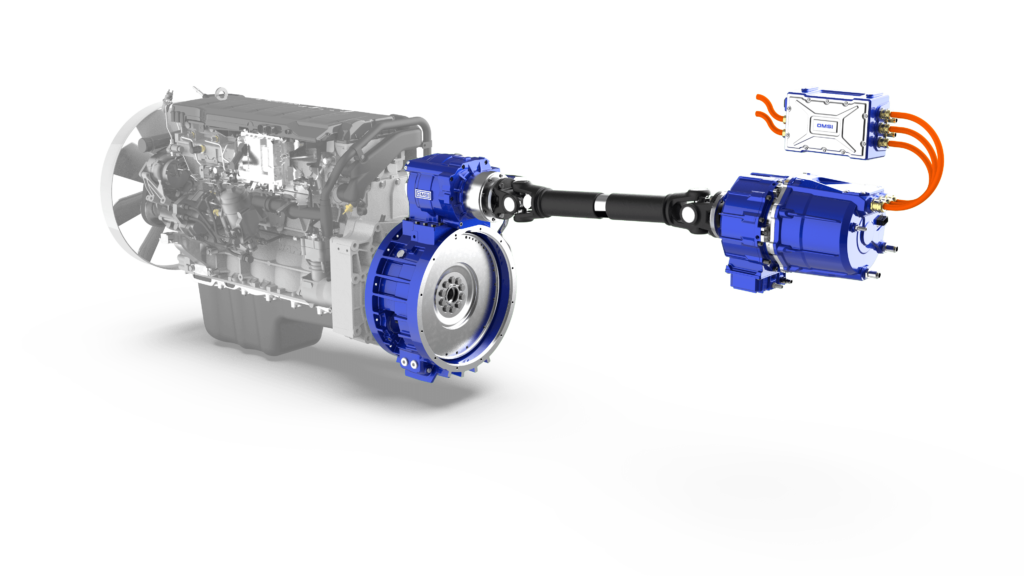

INTEGRATED PTO/PTI SOLUTIONS

FOR HYBRID DRIVES

Integrated technologies for different power packs: truck, marine, railroad, special machines. Electric driving – Regeneration – ICE boosting

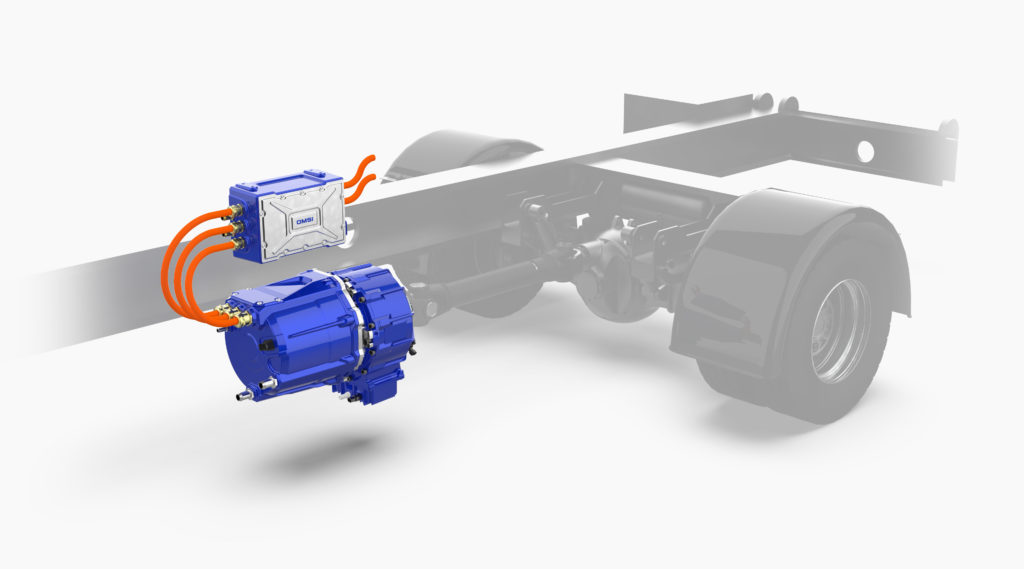

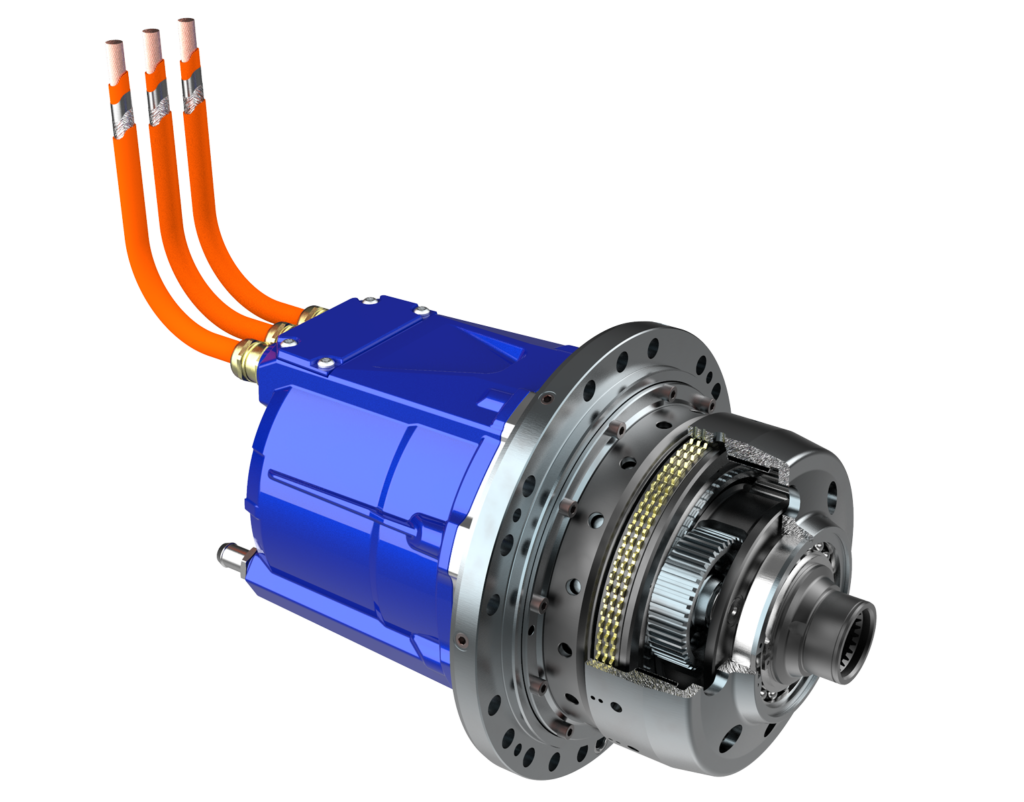

COMPACT ELECTRIC

DRIVE MODULE

High power density e-motor with OMSI compact two speed “shift-on-fly” or single speed gearbox. Most suitable for vehicles with standard axles or for electric conversions. Various ratios available.

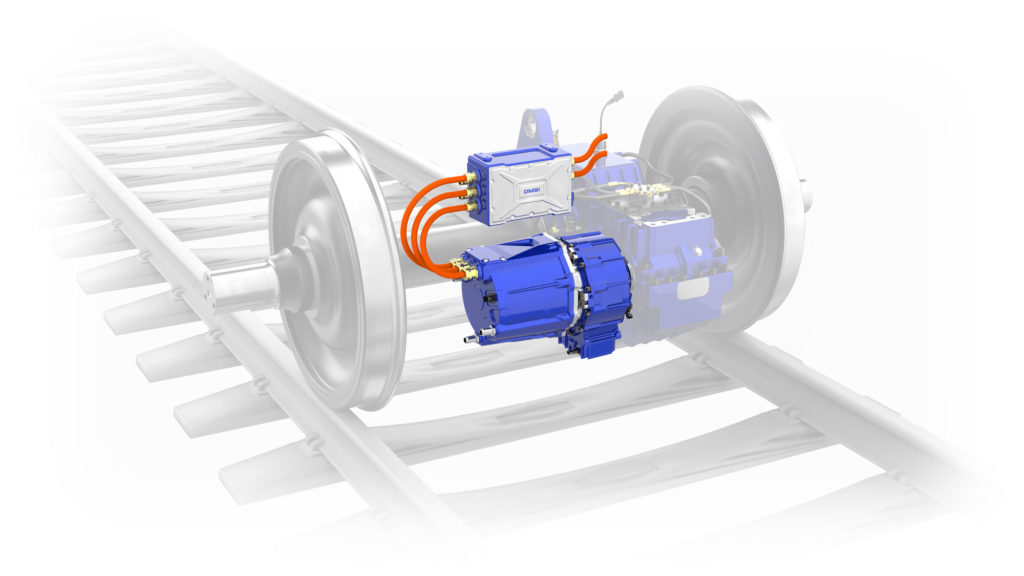

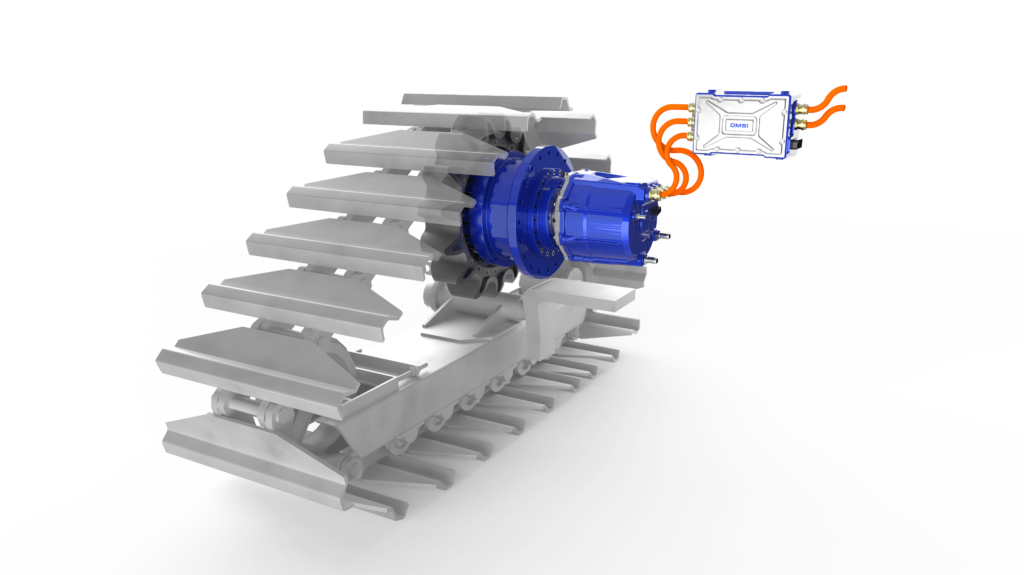

RAILWAY E-AXLE WITH INTEGRATED GEARBOX

Complete railroad reduction units with high density e-drive solution

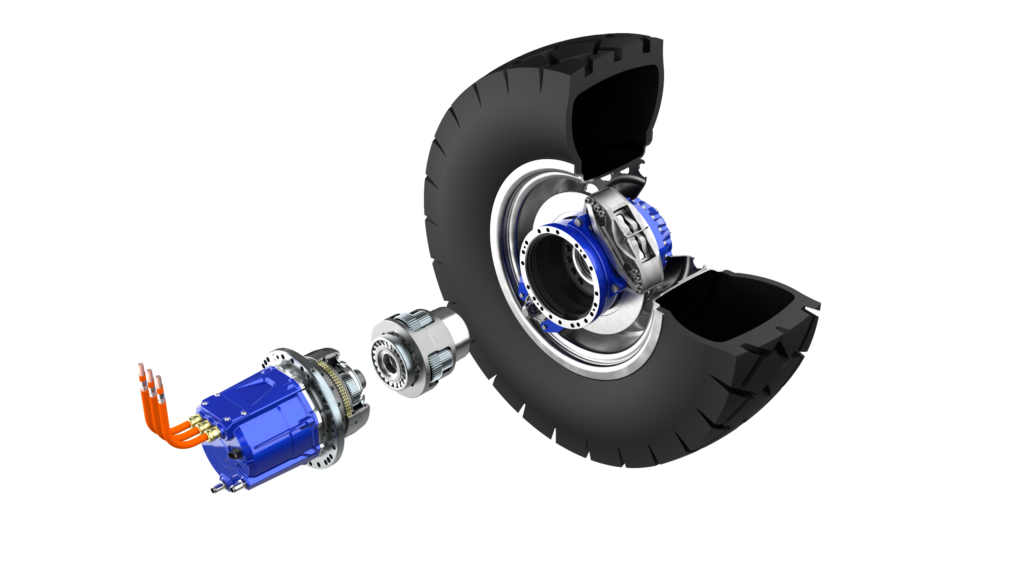

WHEEL HUB AND SPROCKET DRIVE

Two speed planetary module suitable for hub drives and sprocket drives. This solution can integrate high torque final drives and brakes.

MODULE

FOR HYBRID AND ELECTRIC

VEHICLES

2-SPEED E-GEARBOX

| MAX INPUT TORQUE | 500 Nm |

| MAX INPUT SPEED | 11.000 RPM |

| REDUCTION RATIO OF 1ST GEAR | 5,0:1 – 7,1:1 |

| REDUCTION RATIO OF 2ND GEAR | 3,4:1 – 4,5:1 |

| FINAL REDUCTION STAGE RATIO (OPTIONAL) | UP to 7,6:1 |

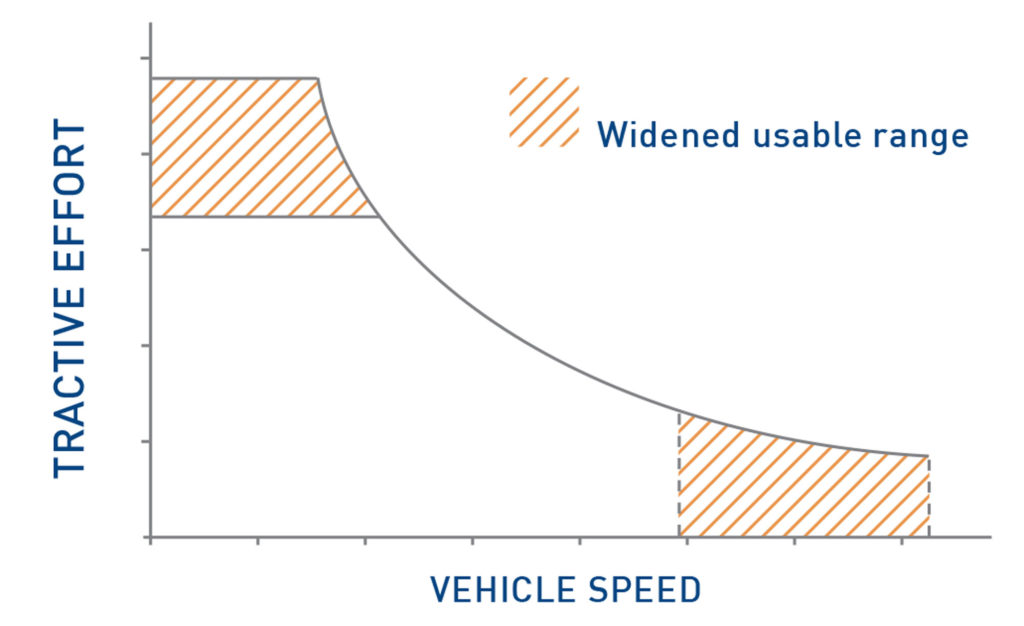

IMPROVED TRACTION CHARACTERISTIC

SYSTEM ADVANTAGES

Two speed powershift design ensures optimal vehicle performance. Both higher tractive effort and higher top speed can be achieved compared to a single speed system.

ELECTRIC DRIVE

SYSTEM ENGINEERING

TECHNICAL ASSISTANCE AND

COMPLETE SOLUTIONS

OMSI Hybrid & Electric expert team can support customers from initial feasibility study up to final implementation for the complete power propulsion system. Powertrain design – equipment implementation – cooling system design

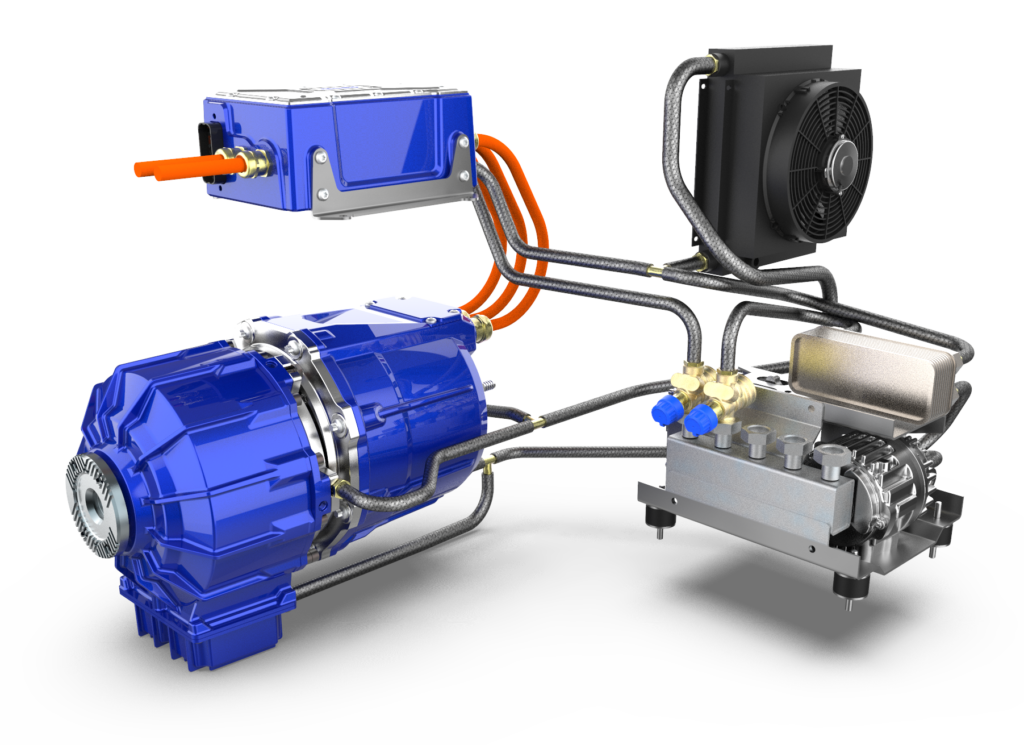

COOLING SYSTEM MODULES

OMSI is able to study and offer electrification-specific cooling systems, dealing with different operating temperatures and cooling media of each sub-system (motor, battery pack, inverter, transmission etc.)